FC1000

Weighing indicator

Product outline

FC1000 is the weighing indicator with various features such as the white LCD main and sub display, dust and drip protection (Equivalent to IP65), accumulation function, data recording on SD Card, and high-speed A/D conversion rate of 1.2kHz

SD card slot

You can write and read setting parameters from SD cards, while recording weighing results & data when abnormalities occur.

■ Calibration value & Error logs are automatically recorded You can identify the indications of faulty load cells and replacement timing.

Date & time of errors occurred can be displayed, as well as the record of how the errors are made (through key control, communication, I/O, etc).

■ Data recording of weighing results Monitor management of raw material, equipment operation rate and so on.

Long-term trend can be observed as well.

■ Restore setting parameters with just one touch

・You can copy setting parameters to another replaced FC1000.

・Multiple FC1000s can use the exact same settings.

・You can restore the initial setting when you first install FC1000. (It will be saved as initial value separately from the setting parameters).

Depth of 99mm

Miniaturization of control panel & panel space saving.

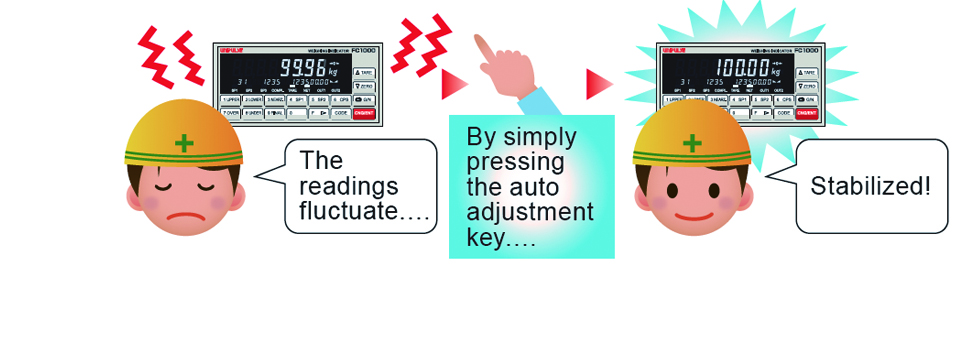

High performance filter & Auto filter adjustment

With combination of low pass filter (0.1 to 300Hz) which corresponds to various vibration and moving average filter (OFF, 2 to 512) that is effective for periodic vibration, automatic searching for optimal value with accuracy and stability can be achieved. (You can manually adjust settings too).

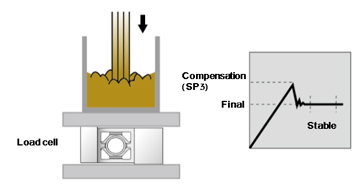

Minus compensation

High-pressure liquid filling & powder feeding can be done.

Equivalent to IP65 protection

By placing the rubber seal when mounting on the panel, the front panel can be protected from moisture and dust damage.

High sampling rate & resolution

High performance digital low-pass filter can be adjusted at 0.1Hz increment. As it is resistant to vibration, measurement can be performed quickly and precisely.

Load cell signal level display (-2.51mV/V to 5.1mV/V)

The output signal level of load cell can be displayed in mV/V for monitor purpose.

Malfunction indicator or faulty sensor can be differentiated easily.

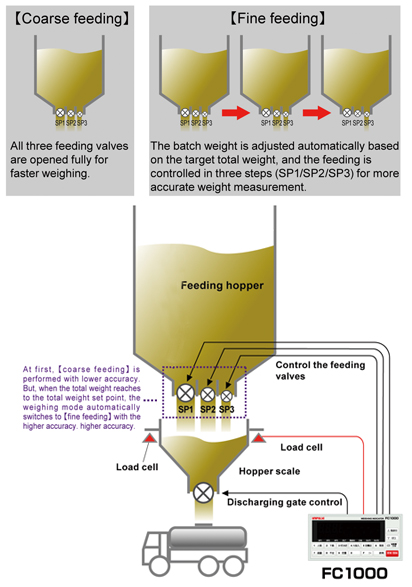

Total weight control function

The batch weighing with a low capacity scale enables the fast and accurate measurement of larger total weight.

Bright white LCD display with the useful 20 digits sub display

The sub display can be used to show the cumulative weight, code/preset number, etc….

6 digit display

24 bit A/D convertor enables 6 digit display.

Memory for 32 weight settings

32 different weight settings can be saved in the memory and selected through I/O or interface.

Batch weighing can be performed easily.

Equivalent input calibration

Theoretical calibration can be performed easily by registering the capacity and rated output of load cells.

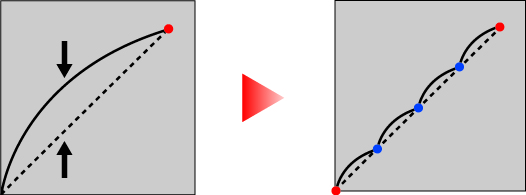

Multipoint calibration (linearization)

Three additional points can be defined in the middle between zero and span for better linearity.

Even though the scale has poor linearity, it can be corrected to be a highly accurate scale.

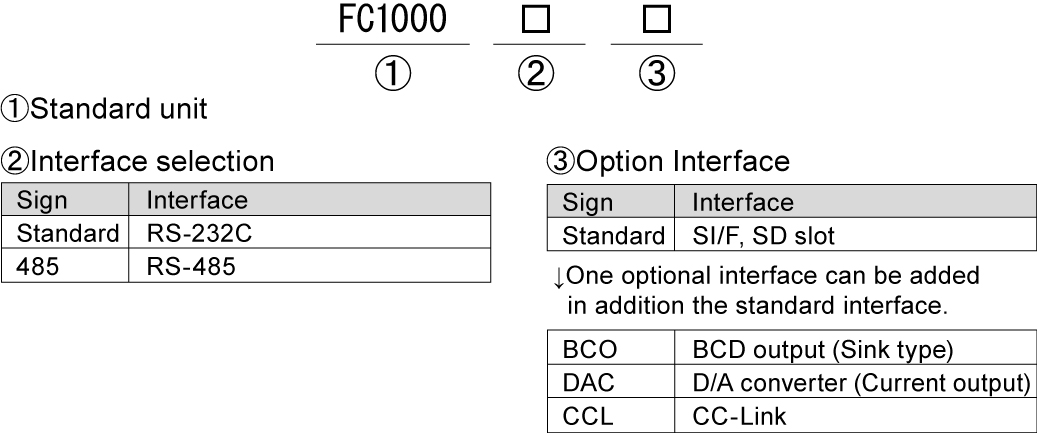

Structure of product code

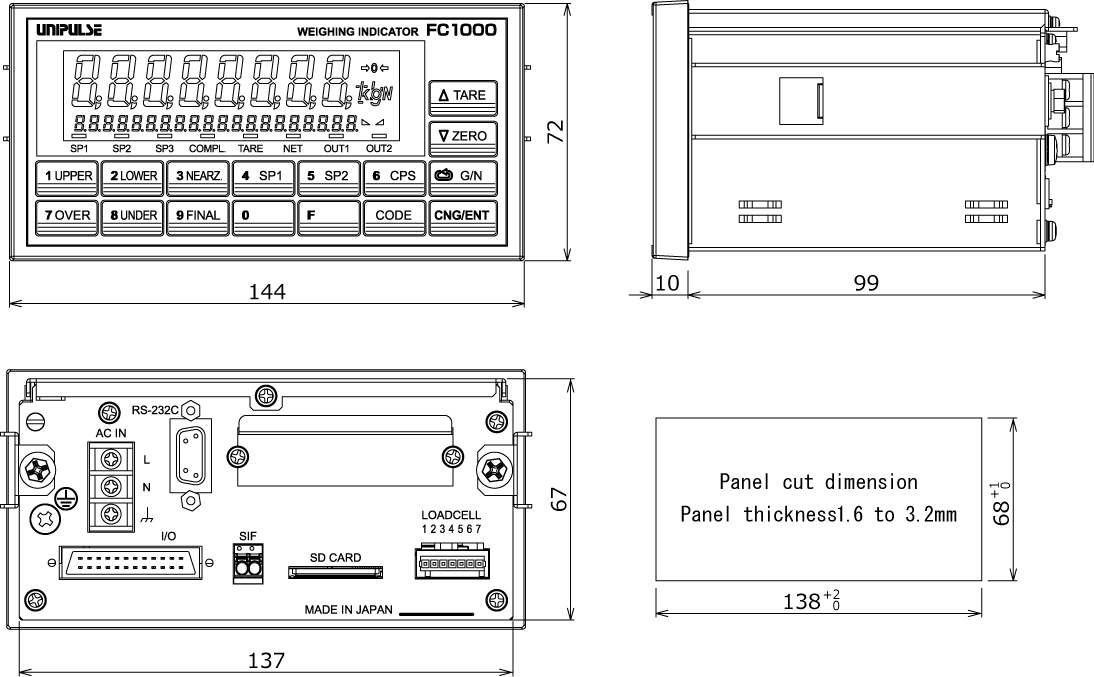

External dimension

Specifications

Analog section|Display section|Setting section|External signal|Interface|General performance|Attachments

| Analog section | |

| Excitation voltage | DC5V±5% Output current:90mA Remote sense type (Up to 6 350Ω load cells can be connected in parallel) |

|---|---|

| Signal input range | -2.5 to +5.1mV/V |

| Zero adjustment range | Automatic adjustment by digital processing -2.5 to +2.0mV/V |

| Span adjustment range |

Automatic adjustment by digital processing 0.02 to +3.0mV/V |

| Gain correction | Up to three point multi-point calibration is possible using linearization function |

| Min. input sensitivity | 0.15μV/count |

| Accuracy | Non-linearity: within 0.01%FS Zero drift: 0.0002%FS/℃ Typ Gain drift: 1ppm/℃ Typ |

| Filter | Digital low-pass filter 0.1 to 300.0 Hz Moving average filter OFF, 2 to 512 times |

| A/D converter | Speed: 300 times/sec., 1200 times/sec. Resolution: 24bit binary |

| Display section | |

| Display Unit | 7-segment LCD display Main display: 8 digit(14.4mm character height), Sub-display: 20 digit (4.3mm character height) |

|---|---|

| Display value | 5 digit sign: negative display at the highest digit (Up to 6 digits) |

| Unit | None / kg / g / t / lb / N |

| Decimal point | 0, 0.0, 0.00, 0.000 |

| Weight errors | “LOAD”: sensor signal level is above the signal input range, “-LOAD”: the sensor signal level is below the signal input range, “OFL1”: the Net weight is over the limit, “OFL3”: the GROSS weight is over the limit |

| Display frequency | 1, 3, 6, 13 or 25 times/sec. |

| Status display | SP1 / SP2 / SP3 / COMPLETE / TARE ON / NET / OUT1 / OUT2 |

| Setting section | |

| Setting method | By operating the membrane keys or through interface |

|---|---|

| Memory of set value | Default settings: stored in NOV.RAM (non-volatile RAM) Time: backed up by lithium battery Other setting values: stored in F-RAM (non-volatile RAM) |

| Protection of set value | Settings can be protected with the software LOCK |

| Setting item | – Upper Limit / Lower Limit / Near Zero / Set Point 1 / Set Point 2 / Compensation / Over / Under / Final – Comparison Inhibit Time 1 / Judging Time / Complete Output Time / Compensation Feeding Time / AZ Times / Judging Times / Auto Free Fall Compensation Limit / Comparison Inhibit Time 2 / Tare Weight – Weighing Function 1 / Weighing Function 2 / Weighing Function 3 / Sequence Mode / Lock Function Keys / Discharge Time / Motion Detection(Time & Range) / Zero Tracking Time / Zero Tracking Range – Balance Weight Value / Minimum Scale Division / Net Over / Gross Over / DZ Regulation / Function Selection / Gravitational Acceleration / Sampling Speed / Sub display Selection – D/A Output Mode / D/A Zero Output Weight / D/A Full Scale / RS-232C / RS-485 Setting / ID Number / Delay Time / CC-Link Number / CC-Link Station / Level Signal Priority – Input Selection 1 / Input Selection 2 / Output Selection 1 / Output Selection 2 / Output Selection 3 / Status Display Selection / Automatic Filter Adjustment / Digital Low Pass Filter / Moving Average Filter – Batch Count / SP0 / Total Weight Comparison Selection / Target Total Weight (Upper 4 digit) / Target Total Weight (Lower 5 digit) / Total Weight Set Point (Upper 4 digit) / Total Weight Set Point (Lower 5 digit) – Read Settings from the SD Card / Write the Settings on the SD Card / Protect Settings / Extended Function Selection 1 / Extended Function Selection2 / Total weight control function – Average Weight / Max. Value / General Standard Deviation / Data Count / Latest Data / Max.-Min. / Option Board Confirmation – Span Calibration / Equivalent Input Span Calibration / Equivalent Input Zero Calibration / Linearize Calibration1 / Linearization Calibration2 / Linearization Calibration3 / Linearization Calibration ON/OFF / Calibration Point Confirmation / Password / Zero Calibration |

| External signal | |

| Output signal (12) | Selectable/configurable Open collector output Vceo=30V, Ic=120mA |

|---|---|

| Input signal (8) | Selectable/configurable Non-voltage contact input (internal circuit power supply voltage 12V) |

| Interface | |

|---|---|

| · SI/F interface · SD card slot · Select either RS-232C or RS-485 interface · BCD parallel data output interface (Option) · D/A converter current output (Option) · CC-Link interface (option) |

| General performance | |

| Power supply voltage | AC100 to 240V (+10% -15%) (free power source 50/60Hz) |

|---|---|

| Power consumption | 5W typ |

| Operating conditions | Temperature Operating temperature range: -10 to +50℃ Storage temperature range: -20 to +60℃ Humidity 85%RH or less (non-condensing) |

| Dimensions | 144(W)×72(H)×109(D)mm (excluding the projections) |

| Weight | Approx. 850g |

| Attachments | |

|---|---|

| · AC input cord (nominal rating 125V) 3m···1 · FCN series I/O connector (with cover)···1 · Load cell input connector···1 · Operating tool···1 · Jumper cable···2 · SD card (1GB)···1 · Rubber seal for dust & drop-proof protection···1 · Quick manual···1 · BCD output connector (when BCO option is selected)···1 · D/A converter connector (when DAC option is selected)···1 · CC-Link connector (when CC-Link option is selected)···1 |

Download

|

Product catalogue(PDF)

|

FC1000 Product catalogue Dowmload | |

|---|---|---|

|

Operation manual(PDF)

|

|

|

|

External dimention

|

DXF

(ZIP) |

|

|

PDF

|

||

|

Support tools

|

||

|

Software

|

||

- User registration is required to download operation manuals, external dimentions, support tools and software.

- Acrobat Reader software from Adobe Systems is required to view PDF files.